Cladded and Weld Overlay Products:

Metal Cladding

Cladded & Weld Overlayed Components for Oil & Gas, Refinery and Petrochemicals Industry

|

CLADDING & WELDOVERLAY:

CLAD & WELD OVERLAYMATERIALS:

| BASEMATERIAL | Carbon Steel, Stainless Steel &LowAlloy Steel |

| CLADMATERIAL | SS304,SS316L,SS317L,SS410,UNSN08825, UNSN06625, HastelloyC22, HastelloyC276, HastelloyB3, UNSN04400 |

| WELDOVERLAYMATERIAL | ER410S,430, ER308L,309L, ER309LMo, 316L, 317L, UNSN08825, UNSN06625, HastelloyC22,Hastelloy C276, HastelloyB3, UNSN04400 |

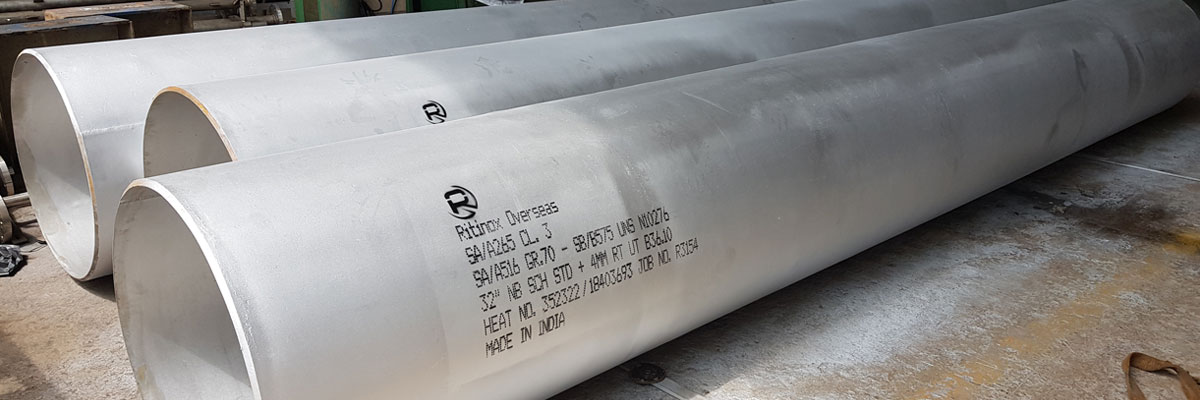

CLADDED PIPES, FITTINGS & FLANGE:

|

Ritinox offers following cladded & weldoverlayed components of various sizes & thicknesses with cladding by weld overlay or explosion bonding:

| PIPES | DIAMETER | THICKNESS | CLAD/WELDOVERLAY THICKNESS |

| Welded Pipes | 2″NB to 42″NB | Minimum 7mm & above | 1.5mm to 4.5mm |

| Seamless Pipes | 2″NB to 42″NB | Minimum 7mm & above | |

| FITTINGS | SIZE | THICKNESS | WELDOVERLAY THICKNESS |

| Elbows | 2″ & above | Minimum 7mm & above | 1.5mm to 4.5mm |

| Reducers | 2″& above | Minimum 7mm & above | 1.5mm to 4.5mm |

| Tees | 2″ & above | Minimum 7mm & above | 1.5mm to 4.5mm |

| Weld olets | 2″ & above | Minimum 7mm & above | 1.5mm to 4.5mm |

| Sockolets | 2″ & above | Minimum 7mm & above | 1.5mm to 4.5mm |

| FLANGES | SIZE | THICKNESS | WELDOVERLAY THICKNESS |

| WNRF,BLRF, WNRTJ | 2″ & above | Minimum 7mm & above | 1.5mm to 4.5mm(orasreq.) |

| VESSELS&HEADRES | DIAMETER | THICKNESS | WELDOVERLAY THICKNESS |

| VESSELS | 600mm to 3500mm & upto 20mtr. Long | Minimum 7mm & above | 1.5mm to 4.5mm |

WELD SURFACING AND OVERLAY:

|

| Ritinox has developed extensive range of procedures and techniques for weldoverlay applications for the Oil & Gas, Petrochemical and Refineries. | Salient features of ETR -S | |

| Maximum Bore Depth | : upto 4m | |

| Weldable Bore Dia | : 45 to 320mm | |

| Welding Speed | : 340 to 450mm/min | |

| Deposition Rate | : 1.7 to 2.5kg/hr | |

| To cater to the needs of its clients for weld overlayeditems, Ritinox has indigenous Automatic Overlaying Machines and EndlessTorch Rotation (ETR) welding machine from Fronius which has advantage of overlaying on 3D curved surfaces. | Automatic Overlaying Machines ( 3 Nos.) | |

| Maximum Bore Depth | : upto 3 mtrs | |

| Weldable Bore Dia | : 100 to 1000mm | |

| Welding Speed | : 100 to 250mm/min | |

| Deposition Rate | : 1 to 2 kg/hr | |

| The ETR-Scombines thefeatures of the conventional TIG Hot Wire Cladding System as regards weld quality, functionality and software features. | Pipe ID overlaying Machine: | |

| Maximum Pipe Length | : 1 2 mtrs | |

| Size | : 200 to 1000mm | Function of Arc Voltage Control (AVC) aids in deposition of uniform thickness of weld overlay on various surfaces. |

QUALITY CONTROL SYSTEM:

|

|

FORClad Fabrication:

|

FORWeld Overlayed Items:

|

QUALITY CONTROL SYSTEM:

Ritinox followsstringentqualitycontrolsystemsothatall theparametersarecompliedandcustomergethigh qualityproduct: