Branch Fittings (Outlets):

Ritinox Overseas LLP is a leading manufacturer of branch fitting, buttweld pipe oulets, socket weld and threaded pipe oulets in all material grades and wall thicknesses and in compliance with international standard MSS-SP-97. Our production range includes pipe oulets such as Welding Outlet, Socket Outlet, Threading Outlet, Lateral Outlet, Elbow Outlet, Nipple Outlet and Sweep Outlet. We can also manufacture and supply forged flanged outlet fitting in Class 150 to Class 2500 flange ratings. Lateral and elbow oulets can be supplied in butt-weld, socket-weld, and threaded end connections. Weld pipe oulet is one of the most commonly used branch connection fitting. It is widely considered a buttweld fitting, as it is welded onto the outlet of the pipe. A welding outlet helps in minimizing the stress concentrations and provides integral reinforcement without the need for reinforcing the weld.

|

|

|

|

Welding Outlet |

Thread Outlet |

Socket Outlet |

Lateral Outlet |

|

|

|

|

Sweep Outlet |

Nipple Outlet |

Braze Outlet |

Couple Outlet |

|

|

|

|

Flexible Outlet |

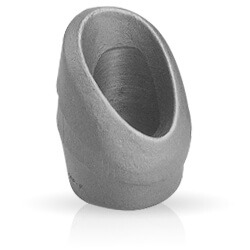

Elbow Outlet |

Flange Outlet |

|

The materials we use are as follows:

| Nickel Alloy | ASTM / ASME B/SB 564 UNS N02200 (NICKEL 200), UNS N04400 (MONEL 400), UNS N08825 INCOLOY (825), UNS N06600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS N06625 (INCONEL 625), UNS N010276 ( HASTELLOY C 276), ASTM / ASME B/SB 160 UNS N02201 (NICKEL 201) ASTM / ASME B/SB 472 UNS N08020 ( ALLOY 20 / 20 CB 3) |

| Copper Alloy | ASTM / ASME B/SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS NO. C 83600,ASTM / ASME B/SB 151 UNS NO. 70600, 71500, C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30), ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200. |

| Stainless Steel | ASTM / ASME A/SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H. |

| Duplex and Super Duplex Steel | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61. |

| Carbon Steel | ASTM / ASME A/SA 105. |

| Low Temp Carbon Steel | ASTM / ASME A/SA 350 LF 2. |

| High Yield Carbon Steel | ASTM / ASME A/SA694 X55, X60, X65, X70 |

| Alloy Steel | ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91. |

| Titanium | ASME ASTM SB/B381 Grade 2, Grade 5, Grade 7 |

Documents: We supply the following documents on demand along with our supplies:

- 1. Material test certificate as per EN 10204 3.1 OR EN 10204 3.2

- 2. Back up documents such as:

- Raw Material Test Certificate

- Lab Test Reports (Chemical, Mechanical, Hardness, IGC, etc.)

- Dimensional Reports

- Heat Treatment Charts

The materials we use are as follows:

| Carbon | SA234 WPB, SA234 WPC,SA42 WPL6, SA42 WPL3, WP1. MSS-SP75 WPHY,WPHY 46,WPHY 52,WPHY 56,WPHY 60,WPHY 65, WPHY 70 DIN 1629 St37, RST37.2 St52 |

| Stainless | ASTM/ASME SA403 304,304L ,316, 316L, WP304L, 3 WP316 WP347 (H) ,WP317 (L),WP321. DIN 1.4301, 1.4306, 1.4401, 1.4571 JIS SUS304,SUS304, SUS304L, SUS316, SUS316 |

| Alloy | A400(N04400), A200 (N02200), A201 (N02201), A800 (N08800), A800H (N08810), A800HT (N08811), A825 (N08825), A600 (N06600), A625 (N06625), C276 (N10276), C22 (N06022), B2 (N10665) |

| Others | F11,F12, F22, F5, F9, F91, F92 |

Outlets Type:

Welding oulet

Welding oulet

|

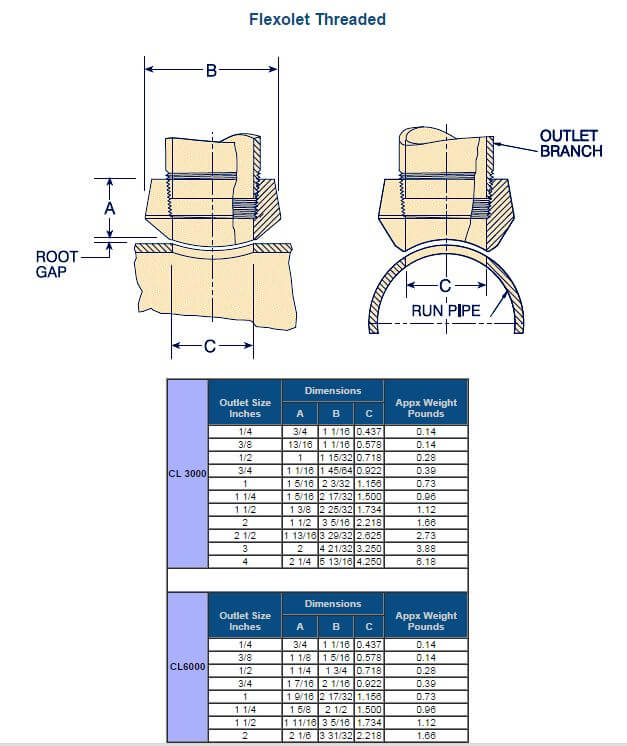

Threding outlet

Threding outlet

|

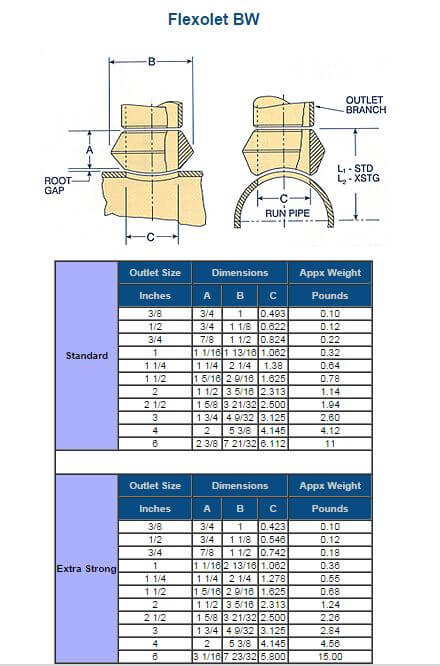

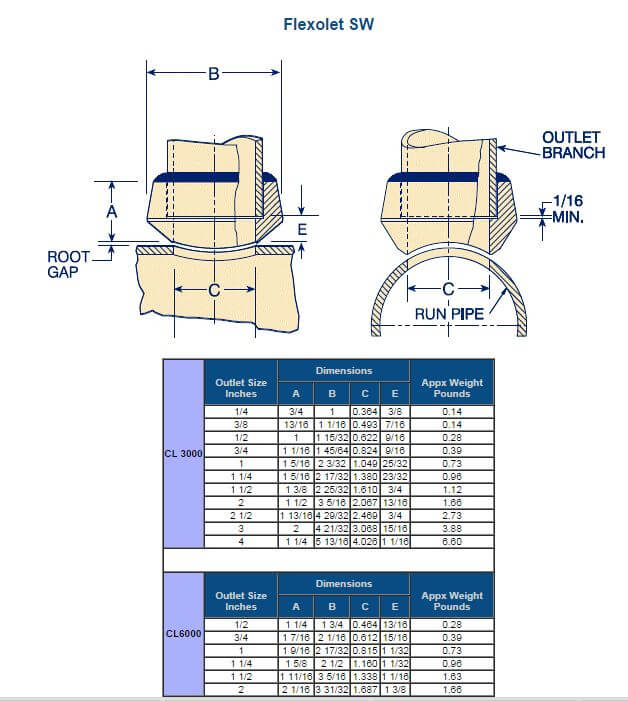

Flexible outlet

Flexible outlet

|

Lateral Outlet

Lateral Outlet

|

Elbow outlet

Elbow outlet

|

Sweep Outlet

Sweep Outlet

|

Insert Welding Outlet

Insert Welding Outlet

|

Nipple outlet

Nipple outlet

|

Braz outlet

Braz outlet

|

Couple outlet

Couple outlet

|

Socket Outlet

Socket Outlet

|